Vendors provide measurement data, AND THAT'S IT. Statistical computations on the measurement data, and generation of reports and graphs, are all done by balloonDigest. You get the same reliable state of the art analysis, done the same way and in the same format every single time.

- Load a 2D drawing which has balloon meta data. Use balloonDigest to rapidly find balloons.

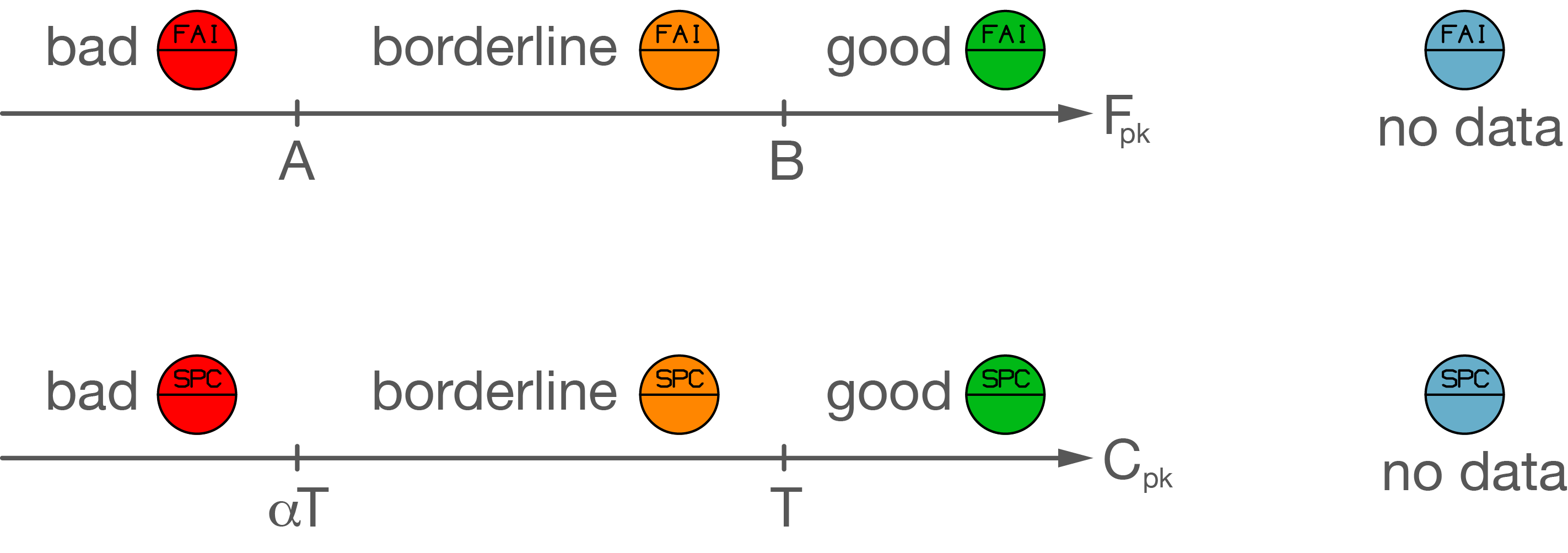

- Load vendor data and watch balloonDigest bring your 2D drawing to life, coloring FAI and SPC balloons according to the performance of the data. Each balloon becomes a clickable button which shows the data in detail.

where T is the per-balloon $C_{pk}$ target.

| A = | B = | $\alpha$ = |

For FAI data on a unilateral spec, we introduce $$F_{pk}=\frac{USL-b}{2\cdot USL},$$ where $b$ is the maxium data value, and where $USL$ is the upper spec limit on the dimension. As with the bilateral case, the higher the value of $F_{pk}$ the better, with a best possible value of 0.5. Here are some examples:

For SPC data on a bilateral spec, we use $$C_{pk}=\min\left\{\frac{\mu-LSL}{3\sigma},\frac{USL-\mu}{3\sigma}\right\},$$ where $\mu$ and $\sigma$ are the mean and standard deviation of the data, and where $LSL$ and $USL$ are the lower and upper spec limits on the dimension. As with $F_{pk}$, higher values of $C_{pk}$ are better. Here are some examples:

For SPC data on a unilateral spec, we use $$C_{pk}=\frac{USL-\mu}{3\sigma},$$ where $\mu$ and $\sigma$ are the mean and standard deviation of the data, and where $USL$ is the upper spec limit on the dimension. As with the bilateral case, higher values of $C_{pk}$ are better. Here are some examples:

A unilateral dimension is one that doesn't make physical sense for values either greater than or less than the nominal value. For instance, concentraction can never be more than 100%, and flatness can never be less than 0. Unilateral dimensions on mechanical parts seem to consist exclusively of values that are ideally zero, but that stray positive because of imperfections, (e.g., flatness, perpendicularity, cylindricity, profile tolerance, etc).

Most bilateral values arise from of a sequence of independant random processes, and as a result are normally distributed. Unilateral values aren't so simple. Consider throwing darts at a target, and keeping track of the distance the darts are from the target center. Suppose that for any set of axes you may establish on the 2D target surface, the x coordinates of the dart locations are normally distributed. Then, the squares of the distances of the dart locations to the target center will have a Chi-squared distribution with 2 degrees of freedom. In the case of an N dimensional target, the Chi-squared distribution will have N degrees of freedom. Unilateral dimensions on mechanical parts correspond to an N dimensional target, where N varies depending on the details of the processes used to create the part.

| Part Number | 200-12345-000 | ||||||||

| Part Name | exceptional part | ||||||||

| Vendor | some vendor | ||||||||

| Date | YYYY.MM.DD | ||||||||

| Part Info | xyz | ||||||||

| Balloon Type | Balloon ID | Location # | |||||||

| FAI | 23 | 1 | 3.145 | 3.235 | 3.055 | ||||

| FAI | 23 | 2 | 3.211 | 3.212 | 3.324 | ||||

| FAI | 23 | 3 | 3.532 | 3.132 | 3.344 | ||||

| SPC | 12 | 1 | 33.245 | 33.032 | 33.179 | 33.865 | 33.976 | ... | 33.054 |

| SPC | 16 | 1 | 23.876 | 24.032 | 24.179 | 23.980 | 23.982 | ... | 24.021 |

| FAI | 4 | 1 | 7.988 | 7.796 | 7.832 |